ZHXT Heavy Duty Suspension Conveyor

The ZHXT series is divided into X348, X458, and X678 in imperial systems and XT80, XT100, and XT160 in metric systems. The heavy-duty suspension conveyor is composed of a driving device, a tensioning device, a slewing device, a traction chain, a slide frame, a track, etc.

Key words:

ZHXT Heavy Duty Suspension Conveyor

Classification:

- Product Description

-

- Commodity name: ZHXT Heavy Duty Suspension Conveyor

The ZHXT series is divided into X348, X458, and X678 in imperial systems and XT80, XT100, and XT160 in metric systems. The heavy-duty suspension conveyor is composed of a driving device, a tensioning device, a slewing device, a traction chain, a slide frame, a track, etc.

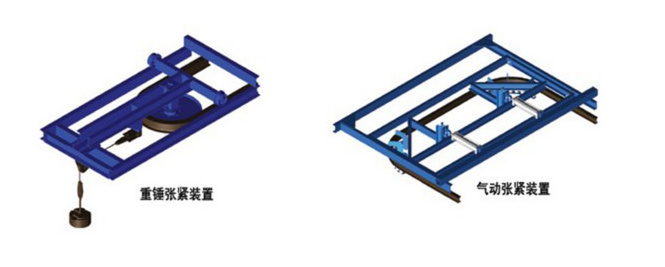

The ZHXT series is divided into X348, X458, and X678 in imperial systems and XT80, XT100, and XT160 in metric systems. The heavy-duty suspension conveyor is composed of a driving device, a tensioning device, a slewing device, a traction chain, a slide frame, a track, etc. Chain In a suspended conveyor, the chain is the component that transmits power. The proper selection of the traction chain directly affects the service life and performance of the conveyor. The chain consists of an inner link plate, an outer link plate and a pin, and can be easily assembled and disassembled without tools. Each component is made of special steel through precision forging. After heat treatment, it has the advantages of high strength, heat resistance, friction resistance, corrosion resistance and impact resistance. The overall bending performance of the chain is good, and it can be transported at small vertical inclinations and large horizontal turns, with low noise during transportation. The pin does not rotate when running, has good wear resistance, and is easy to replace.

Heavy-duty conveyor chain technical parameters

Model

Parameters

A

B

C

D

P

Maximum breaking tension KN

Maximum allowable tension KN

Self-weight Kg

WT348

28

41

21

13

76.6

98

9

3.1

WT458

37

54

27

17

102.4

187

15

4.65

WT678

54

81

39

22

153.2

320

27

9.43

Forged slide

The function of the sliding frame is to bear the weight of objects, spreaders and chains, and also to bear the resultant force of chain tension in the vertical bending section, and to ensure that the chain runs according to the track line. When the distance between two loaded carriages in the line exceeds 800~900mm, an unloaded carriage can be added in the middle.

Heavy duty conveyor slide technical parameters model A

B

C

D

d

d1

H

h

φ

P

W

W1

3"

100

80

64

80

14

14

20

14

60

76.6

125Kg

250Kg

3×4"

100

80

74

80

14

14

20

14

60

102.4

125Kg

250Kg

4"

136

100

80

73

16.5

20

27

17

82

102.4

250Kg

500Kg

6"

175

160

100

93

20

25

33

21

135

153.2

400Kg

800Kg

Drive unit

The drive device is the power source of the conveyor. There are two types of drives for heavy-duty conveyors, one is an angular drive device and the other is a linear drive device. The angle drive device has the advantages of simple structure and low cost. The disadvantage is that it can only be installed at the horizontal turning point of the traction chain. The conveyor line layout has limitations. Safety pins are used for safety protection. It is generally used in conveyor systems with simple lines; straight lines The driving device is widely used in any linear stroke chain drive. It consists of a sleeve roller transmission chain and a shifting claw. It moves forward by means of the mutual meshing of the driving claw and the detachable chain to ensure the normal operation of the conveyor. The overload protection is installed on the reducer by a support cantilever, and the other end of the cantilever is connected to the drive frame and is equipped with an overload protection spring. Under normal conditions, the driving force is just in equilibrium with the reaction moment formed by the spring. When the resistance in the line is large, the driving torque increases, the reducer body rotates, and the spring is further compressed. When the driving force reaches 1.5 times the rated tension, Touch the travel switch and stop the vehicle.

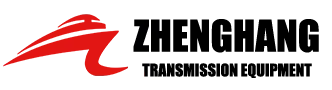

tensioning device

The structure of the tensioning device adopts heavy hammer or pneumatic tensioning, and the smooth wheel or roller row rotates. The tensioning working stroke can reach 700 mm, which can ensure that the initial tension of the chain remains unchanged and the work is reliable, which can meet the safety requirements of the conveyor in any working environment. Work

Previous article

Next article

Previous article

Next article