ZH400 cross chain conveyor

The XF400 series conveyor has the advantages of smooth operation, reliable operation and strong applicability. This series of conveyors uses XF400 series chains, which can not only be used alone in aluminum alloy vertical spraying production lines, but also can be combined with other series of tracks to easily form various types of accumulation conveyor series, making the accumulation conveyors lightweight and occupying less space. Small space and other characteristics, and the price is relatively cheap.

Key words:

ZH400 cross chain conveyor

Classification:

- Product Description

-

- Commodity name: ZH400 cross chain conveyor

The XF400 series conveyor has the advantages of smooth operation, reliable operation and strong applicability. This series of conveyors uses XF400 series chains, which can not only be used alone in aluminum alloy vertical spraying production lines, but also can be combined with other series of tracks to easily form various types of accumulation conveyor series, making the accumulation conveyors lightweight and occupying less space. Small space and other characteristics, and the price is relatively cheap.

The XF400 series conveyor has the advantages of smooth operation, reliable operation and strong applicability. This series of conveyors uses XF400 series chains, which can not only be used alone in aluminum alloy vertical spraying production lines, but also can be combined with other series of tracks to easily form various types of accumulation conveyor series, making the accumulation conveyors lightweight and occupying less space. Small space and other characteristics, and the price is relatively cheap.

XF400 series conveyors are divided into four varieties according to the lifting weight: XF400A type: single lifting point weight 30kg; XF400B type: single lifting point weight 80kg; XF400C type: single lifting point weight 120kg;XF400 series medium-sized conveyor technical parameters

item

Parameters

XF400A type

XF400B type

XF400C type

XF400D type

Chain pitch

200/250 mm

330/350/400 mm

350/400 mm

400 mm

Allow tension

400 Kg

800 Kg

1000 Kg

2000 Kg

Single point lifting weight

30 Kg

80 Kg

120 Kg

250 Kg

Conveyor speed

0~15 m/min

0~15 m/min

0~15 m/min

0~15 m/min

Horizontal curved rail

radius

600/800 mm

600/800 mm

600/800 mm

600/800 mm

Angle°

15/30/45/90/180

15/30/45/90/180

15/30/45/90/180

15/30/45/90/180

Vertical curved rail

radius

600/800/1000 mm

600/800/1000 mm

600/800/1000 mm

600/800/1000 mm

Angle°

15/30/45

15/30/45

15/30/45

15/30/45

Single drive line length

200 m

200 m

200 m

200 m

Maximum comprehensive wrap angle

1800°

1800°

1800°

1800°

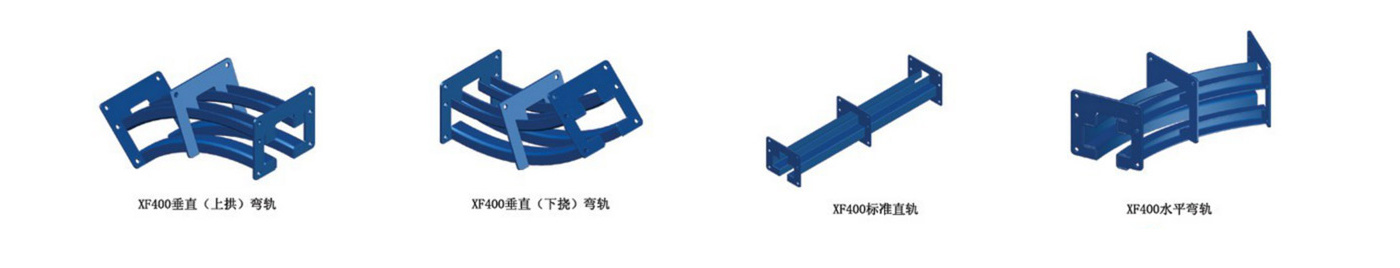

1. System composition

The XF400 series conveyor is mainly composed of main components such as chains, tracks, driving devices and tensioning devices.

1. Traction chain

The traction chain consists of chain plates, pins, intermediate sections and bearing roller sets. The chain plates and pins are made of 40Cr material, which has the advantages of good wear resistance and high strength after heat treatment. The bearing roller set adopts integral bearings, and the material is bearing steel, which has the advantages of wear resistance, high temperature resistance, corrosion resistance, and low running resistance.

A. XF400A type chains are divided into two types, using chains with a pitch of 250 and 400 respectively. The minimum hanging spacing is a full pitch of 250 or 400. Using a chain with a pitch of 400, you can also use special spreaders to achieve half-pitch hanging. The minimum hanging spacing is 200. Single point lifting weight is 30Kg.

There are three types of B.

There are two types of C and

D. XF400D type chain has only one form because of its large single-point lifting weight. The chain pitch is 400, the minimum hanging spacing is 400, and the single-point lifting weight is 250Kg.

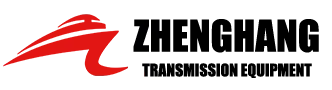

2. OrbitXF400 conveyor tracks include standard straight rails, horizontal curved rails, vertical curved rails, inspection rails, heat-retractable rails, etc. The track is pressed and formed from high-quality steel plates. The standard track length is 6000mm. Installation brackets are installed on both sides of the track. Positioning brackets are installed every 600mm in the middle of the track. The track connection can be connected with bolts or the brackets at both ends can be welded.

3. Driving device

The driving device of the XF400 series conveyor adopts crawler chain linear drive, which ensures safe and stable driving operation with very little noise. In order to prevent the driving device from being damaged when the entire line fails, the driving device is also equipped with a torque limiter, which also ensures that the entire system can be stopped in time when the line fails, protecting the various components of the conveying system from damage.

Previous article

Next article

Previous article

Next article